In 2024 “Sustainable development” is undoubtedly a topic of interest for thousands of industries.

Inside DewertOkin’ smart factory, the sustainable development concepts of “green”, “low carbon” and ESG (Environmental, Social and Corporate Governance) are practiced from the layout of the factory and the configuration of the equipments to the smallest solar-powered street lamps and sensor faucets.

Low-carbon energy – 3.5MW of photovoltaic power generation

As of July this year, DewertOkin Smart Factory will complete the installation of a distributed photovoltaic power plant with 3.5MW capacity. With an annual power generation capacity of 3.57 million kWh, il will save an average of 1,278t of carbon per year, and reduce emissions of harmful carbon particulate by 971t and of carbon dioxide by 3,387t.

While realizing self-sufficiency in power consumption and reducing energy consumption, PV power generation can truly achieve zero output of dust, wastewater, waste residue, noise and other sources of pollution, and help achieve the energy-saving and emission reduction goal of "carbon peak, carbon neutral".

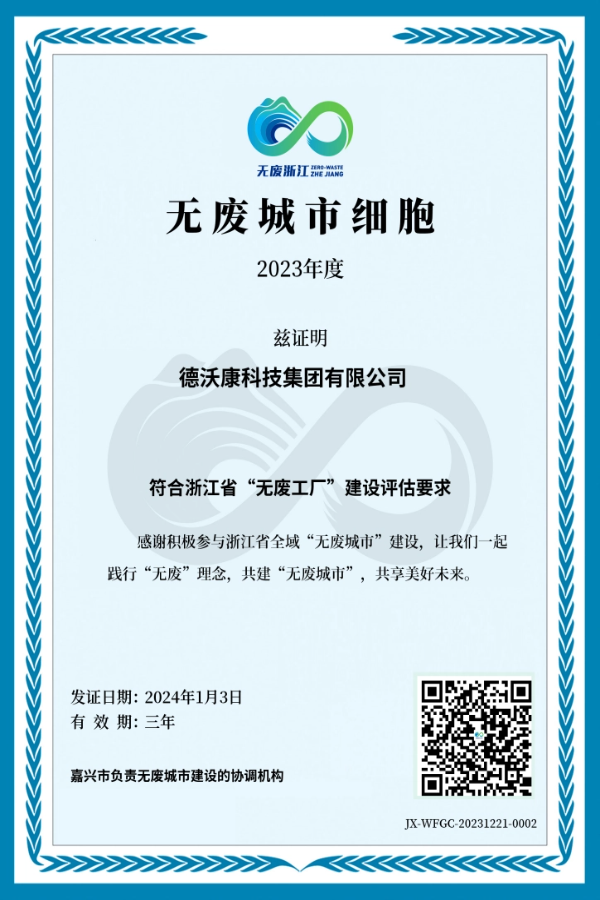

Waste recycling - "Zero-waste Factory"

In terms of waste reduction, resource utilization and harmless disposal of solid waste, the amount of waste landfill is minimized through process transformation, technology update, end-to-end utilization and other methods, and Dewokang Smart Factory was selected as a "Zero-waste factory" in Zhejiang Province in 2023.

In terms of waste recycling, the general industrial solid waste recycling rate of the factory is 100% and the recycling rate of industrial hazardous waste after disposal is 87.69%, other than the implementation of waste sorting and food waste recycling protocols.

In terms of greenhouse gas emissions, advanced exhaust gas treatment equipment has been implemented, and the emission standards have been reached through two-stage sprinkling + dry filtration + activated carbon adsorption.

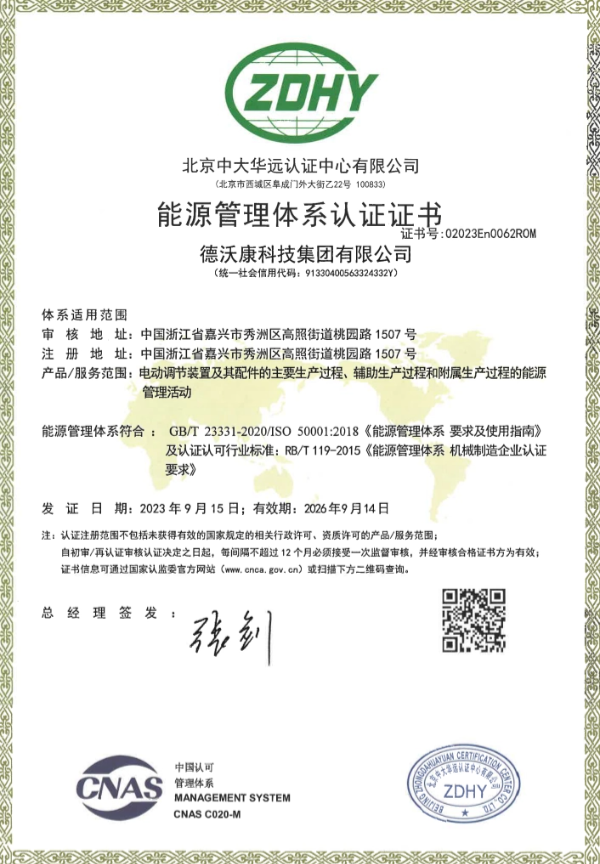

In terms of system management, we have established an energy consumption management system and a real-time monitoring platform to optimize energy consumption and obtained the ISO 50001 energy management system certification.

Smart equipment - a new solution for a "green factory"

Inside the factory, a series of intelligent equipment such as industry-leading automated motor production line, 24-hour running injection molding machine, robot welding and imported fully automatic testing system can be seen everywhere.

The factory-wide linked AGV handling system enables unmanned entry and exit of parts and finished products.

With the application of intelligent equipment, the production process is highly controlled, thus realizing refined management and improving the accuracy and stability of production. Through accurate monitoring of energy loss in each link, resource waste and carbon emission are minimized.

Every move of DewertOkin to "build" green and "practice" green aims to put sustainable development into practice, and make efforts to realize a carbon-neutral circular economy with carbon reduction, zero carbon, or even negative carbon.